IoT software for data visualization and work with digital twin plants

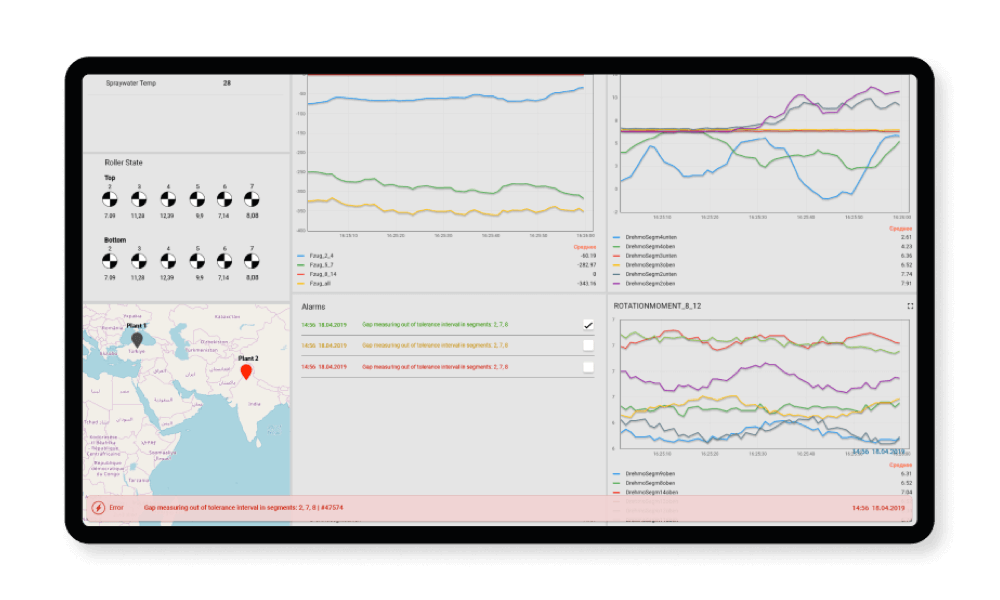

Digital twins of steel production plants with dashboards for data analysis and monitoring.

About the client

The client is one of the leading industrial companies in Europe headquartered in Germany. The company’s primary focus is on the steel production industry.

Objective

The company approached XPG factor with a request to create a software platform to monitor and analyze process data in real time for their continuous casting machines.

Challenge

The customer had outdated software tailored to specific plants. The physical presence of assistants/managers was required at the plant to track the production process, which complicated the process.

Solution

The XPG factor team suggested moving all the data online to solve the client’s problem.

Data storage

By the client’s request the XPG factor team set up the data flow through the cloud infrastructure/environment. This made the approach totally different from the typical use of third-party or self-written services. The solution resulted in faster tasks’ completion, centralized data storage without the need for additional programs, and quicker customization and development. Plants’ digital twins also help to track data at the stage of smelting in real time.

Visualization

The XPG factor team used the Thingsboard IoT framework to visualize the client’s data. The framework provides cross-device connection, signal visualization, and customizable dashboard creation tailored to the client’s needs. As part of the project, we created multiple dashboards that display the current state of the production line, with integrated digital twins of the plants for easy access. Experts can remotely monitor the steel casting machine’s operation through the system.

Security

The team provided security on the project with the help of multilayer user authentication.

Key Features

- Real-time data analytics

- Customizable alarm dispatching

- Measuring results verification

- Comparative analysis of production and maintenance data

- Trends analytics

- Customizable rules engine

Methodology & Transparency

During the project, the XPG factor team followed the Agile methodology. During weekly online meetings with the customer team leader, we shared reports on completed tasks and settled project management issues for the client.

To keep the client informed of their progress, the team also conducted weekly demos to showcase the results.

Team Composition

Technologies

Contact us

Reach out to our experts for customized solutions that fit your business needs.

We appreciate that you've taken the time to write us. Your message was received and we will get back to you with our answer as soon as possible.

Have a great day!